Not known Facts About American Plastics

The Best Strategy To Use For American Plastics

Table of ContentsAmerican Plastics Can Be Fun For EveryoneAmerican Plastics for BeginnersAmerican Plastics - QuestionsThe American Plastics DiariesThe smart Trick of American Plastics That Nobody is Discussing

A little research can aid you over time. It is hard to judge its top quality at initial glimpse with the look of HDPE pipe installation, numerous issues are exposed when making use of, so we can just have a proper judgment after use. Consequently, it is required to select HDPE pipeline installations made by an expert supplier with a good credibility and reputation.A technological expert is important for a good product, especially in the production sector, due to the fact that a tiny blunder will certainly bring about the failing of the whole task. HDPE pipes can replace concrete pipelines in area systems to conserve time and cost of fixing damaged or burst pipes. HDPE pipe is also a cheaper alternative contrasted to other piping materials in regards to operating and installment costs.

The Greatest Guide To American Plastics

HDPE pipes are manufactured with solid straight or rounded sections. It is made of light-weight materials that are simple to transfer and does not require hefty installment devices such as heavy cranes. The mix of light-weight and versatile structures makes it perfect for earthquake-prone locations. The pipelines are not weak and can be easily placed right into a bent area without added jointing or welding.

It has reduced stress and anxiety and unstable turbulence, particularly at high flow rates. Its 'non-adhesive' characteristic makes it excellent for retaining the residential or commercial properties of hydraulic liquids. Also HDPE tin tubes are created in two phases to ravel the inside. Chemicals resistant to HDPE pipelines can pollute the pipeline. The pipe does not work with chemicals and does not melt heat or electrical energy.

HDPE pipes are naturally strong and resistant to damages triggered by external loads, high stress or vibration - https://go.bubbl.us/ed48fd/334f?/American-Plastics. The pipes can endure handling and bend even in cool weather condition. Safe eye liner HDPE internal tubing Smooth Line Pipe Gliding lining utilizing roller combinations Pipe surge Plastic pipes systems Construction of new pipelines Rust resistance, no leaking, high longevity

Heat assimilation, while its difficulties exist, can create strong and reputable joints. Solutions: The strength and resilience of HDPE can be gauged by its ability to withstand temperature levels of around 248F in the short term or even a continuous 230F. If your application consists of gas and fluid to gain access to and raise those temperature levels, HPDE piping is a dependable option.

The 15-Second Trick For American Plastics

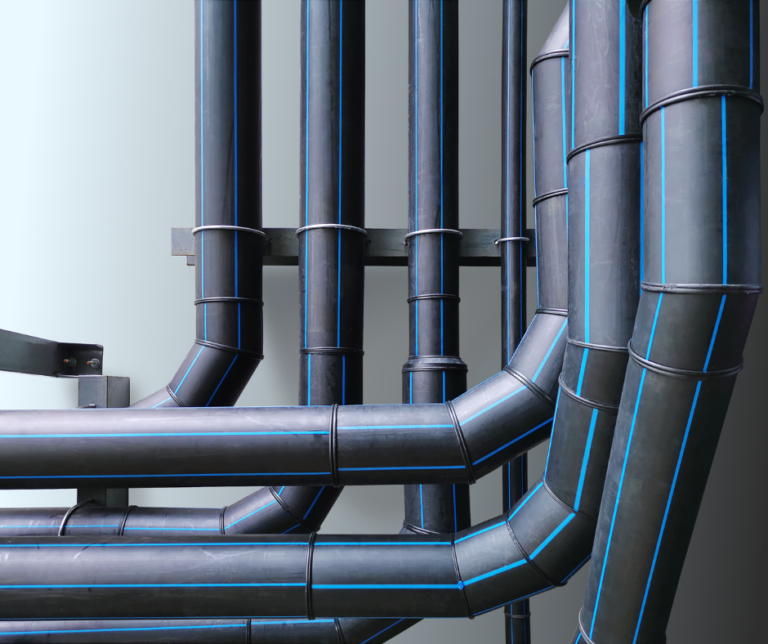

A safe and clean water line/potable water pipeline is constantly dark with blue stripes and pipes passing through fluids, liquids under stress, and procedure gases are constantly loaded with a yellow or black jacket with yellow lines. HDPE pipe product have been used in the basic sector for over half a century and their outcomes are astonishing, developing confidence among makers that they are extra concentrated on HDPE pipe options.

Times because 1991 Removal of material needs with gauge and adjustment. In the stress and anxiety fracture resistance test the cell division demands were damaged. For that reason, it is reasonable in conclusion that HDPE pipe constructed today may have.

Each size category is designed remembering the needs of pressure, flow price, and ecological aspects of the designated application. By matching the correct HDPE pipeline dimension to its usage, designers and service providers can enhance performance and prolong the life expectancy of their piping systems. Measurement and diameter are related ideas in the context of HDPE pipelines.

The Buzz on American Plastics

As mentioned earlier, pipelines with reduced SDR worths have the ability to hold up against higher stress, which is an essential factor to consider in the choice process for tasks that involve high stress or vital applications. high quality hdpe pipe. Choosing a pipe with an inappropriate SDR might cause system failure, security risks, and expensive repair work. Selecting the appropriate HDPE pipeline dimension is critical for the success and efficiency of any kind of piping system

Application Specifics: Tailor your pipe size selection to the specific demands of its application, whether for community, industrial, or other usages. Understanding just how the HDPE pipeline will be made use of, the anticipated flow rates and the stress demands are vital. High-pressure applications could require a pipeline with a higher wall thickness to stand up to the inner stresses, while a lower-pressure, high-flow system may prioritize diameter size to reduce rubbing loss.

A Biased View of American Plastics

Comply with these steps: Analyze the Application: Figure out the pipeline's planned use, consisting of ecological elements and service conditions. Refer to SDR: Check the typical measurement proportion to discover a pipe that can handle the required stress.

Choosing the right HDPE pipe dimension is a delicate balance between various technical specifications and see functional needs - https://medium.com/@danecoffman79701/about. Nonetheless, with mindful factor to consider and precise calculations, you can guarantee the dimension of the pipeline you select will offer your requirements effectively and effectively. Selecting the right HDPE pipeline dimension is important for system efficiency, sturdiness, and cost-effectiveness

Comprehending these elements will ensure ideal efficiency and compatibility throughout your piping system - hdpe pipe suppliers Midland TX. The awaited circulation rate or volume of the fluid being transported is among the primary factors in pipe size choice. A pipeline that is too little can restrict circulation, creating stress loss and prospective obstructions, while an extremely large pipeline may result in unnecessary cost and lowered system efficiency